Why Choose Laser Engraved Asset Plates and Labels?

Laser engraving provides numerous advantages for asset identification:

-

Durability: Laser engraving creates permanent markings that withstand abrasion, chemicals, and outdoor exposure, ensuring long-lasting identification of assets.

-

Clarity: With precise laser engraving technology, our plates and labels offer clear, high-resolution markings, even on small or intricate designs, ensuring readability from a distance.

-

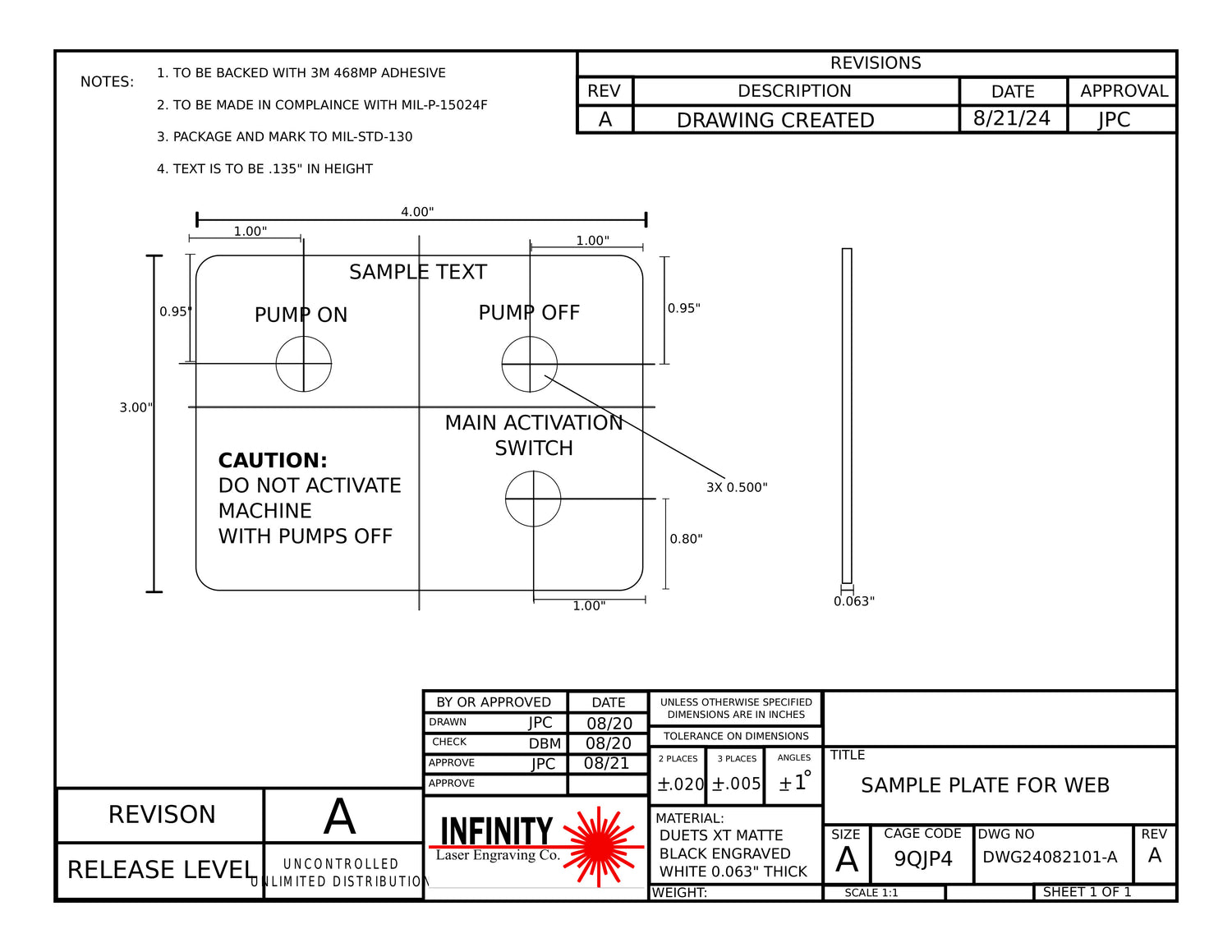

Customization: Our laser engraving process allows for customization of text, logos, barcodes, and serial numbers, meeting your unique identification requirements.

-

Versatility: Laser engraving is suitable for a wide range of materials, including anodized aluminum and coated stainless steel, providing flexibility for various applications.

Features of Our Laser Engraved Asset Plates and Labels:

-

Material Options: Choose from anodized aluminum or coated stainless steel, both known for their durability, corrosion resistance, and suitability for outdoor use.

-

Multiple Thicknesses: Our plates and labels are available in multiple thicknesses, allowing you to select the right option for your specific application and durability requirements.

-

Custom Sizes: We offer custom sizing options to accommodate your unique asset labeling needs, ensuring a perfect fit for your equipment, machinery, or facilities.

-

High-Quality Engraving: Our state-of-the-art laser engraving technology ensures precise, permanent markings that withstand harsh environments and maintain legibility over time.

Applications of Laser Engraved Asset Plates and Labels:

-

Equipment Identification: Clearly label machinery, tools, and equipment with laser engraved asset plates to facilitate inventory management and maintenance tracking.

-

Asset Tracking: Use laser engraved labels with barcodes or serial numbers to track assets throughout their lifecycle, improving accountability and asset management processes.

-

Industrial Applications: Label pipes, valves, and components in industrial settings with durable laser engraved plates and labels for clear identification and safety compliance.

Why Choose Us for Your Laser Engraved Asset Plates and Labels?

-

Quality Assurance: We are committed to delivering high-quality, durable asset plates and labels that meet your exact specifications and exceed industry standards.

-

Custom Solutions: Our team works closely with you to understand your requirements and provide customized solutions tailored to your unique needs.

-

Quick Turnaround: With efficient production processes and quick turnaround times, we ensure timely delivery of your laser engraved plates and labels.

-

Customer Satisfaction: Your satisfaction is our priority, and we strive to provide exceptional customer service, support, and communication throughout the ordering process.

Powder Coated Stainless Steel vs. Anodized Aluminum?

Both stainless steel and anodized aluminum are incredibly wear resistant, but which one should you chose? See the two cross sections below

Above is a cross section of anodized aluminum. When engraving this material the color or pigment is destroyed by the laser leaving blank metal areas. This leaves the design trapped under a hard anodic layer

This is an example of a coated metal which is usually stainless but can also be aluminum. When we process these plates the coating is lasered off showing the exposed metal and giving you your final.

Anodized aluminum has many great features like its hardness, long lasting color, and the fact it is an insulator against electricity. However, stainless steel is preferred for applications requiring maximum durability, strength. However the powder coating is not as durable as anodizing. These are only two of many MANY options.

At the end of the day it comes down to your needs. Our team works closely with you to understand your needs and provide customized solutions using the most suitable material for your project.